Not many people see the products we handle.

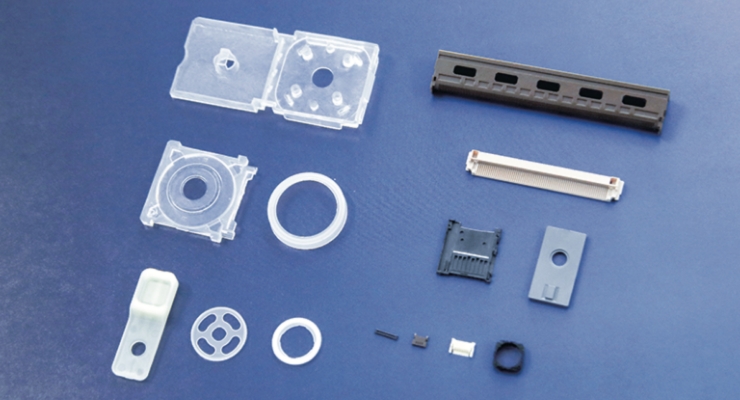

We make fingertip-sized plastic products, such as the connectors and gaskets that connect very small parts inside precision equipment.

These are our company's main products. No matter how small the part is, there can be absolutely no compromise in the technology used.

Each individual molded product measuring just a few microns produces "safety" and "durability" that support and enrich people's lives. We believe that we must be sincere about our products at all times. That is at the core of our manufacturing technology and we believe it is why we are able to continue to support many plastic products today.

Since its founding, ESTOH has worked in fields that are considered to be technically difficult and has taken on the challenge of designing and producing molds and performing injection molding for precision plastic products. Through the production of gaskets and other EV-related products, we will prioritize our reliable technology and our stance of enjoying change and will continue to provide a comfortable life, security and safety for people around the world in order to grow as a company that is chosen by our customers.

I thank you for your continued support and patronage.

President and Representative Director CEO

Kenji Nakamura

We will continue to provide parts solutions business

that is selected by our customers in order to support the comfortable

lives of people and the environment of the Earth.

We carefully listen to the product specifications required by the customer. We make a proposal using the know-how accumulated at ESTOH so far, and confirm the customer's intention in a meeting.We then propose the optimal direction for the manufacturing.

One strength of ESTOH is the fast speed at which we move from planning to design and the start of production.

Our designs bring together all our unique know-how regarding aspects such as runners, cooling and gas removal and make cost reduction possible.

We produce high performance, long-life precision molds.

Our tolerance range for precision in the main parts is only 2 µm.

We fully utilize our technology, which we have continued to improve by being strict about precision.

We perform the high-cycle mass production of high-quality and high-precision products.

We have also established a production system that can respond quickly to requests such as "We want to change the shape".

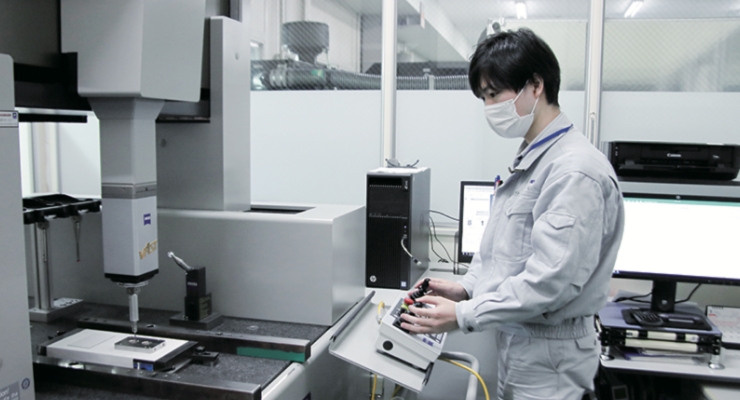

We implement an inspection system that goes even further than the high quality requirements of our customers.

The result of this has been the achievement of zero external claims.

The reduction in the size of items such as personal computers and smartphones has created demand for molding technologies for very small sizes. ESTOH has succeeded in the mass production of gaskets for automotive lithium-ion batteries with a precision of 1/1000 mm.

We operate state-of-the-art molding machines to produce precision injection molded products at high speed, 24 hours a day. We have production facilities that can stably supply more than 400 million high-quality plastic products per month.

Our quality policy is to "Provide peace of mind for our customers" and we have a thorough inspection line with high detection performance. We perform high-level quality checks by using state-of-the-art three-dimensional measuring equipment, tool microscopes, automatic measuring instruments, and dedicated jigs with 1/1000 mm precision.

We acquired ISO 14001 certification in July 2004 and ISO 9001 certification in March 2005. Furthermore, in 2021, we acquired the "IATF 16949" international standard certification for quality management systems, which is specifically for the automobile industry.

We are also considering ESG investment that will create value unique to ESTOH in order to respond to social needs such as SDGs. From now on, we will continue to offer quality that satisfies our customers as we also promote environmentally friendly business activities.

The "ESTOH" name embodies the idea that we should

"Get ahead of the times with creativity and enthusiasm".

ESTOH Co., Ltd. (hereinafter the “Company”) has established this Privacy Policy in order to systematically ensure appropriate handling of personal information, based on the Act on the Protection of Personal Information (hereinafter “Personal Information Protection Act”).